Thickness: 0.1-200mm or as requirement, or as customer’s requirements.

Width: 50mm-2500mm, or as customer’s requirements.

Length: 50mm-8000mm, or as customer’s requirements.

Material: 1050, 1060, 1070, 1080, 1100, 1235, 2011, 2014, 2017, 2024, 2A12, 2A16, 2A06, 3002, 3003, 3004, 3004, 3104, 3204, 3030, 3A21, 5005, 5025, 5040, 5052, 5056, 5083, 5086, 5182, 5754, 5A05, 6003, 6060, 6061, 6082, 6083, 6063, 6061, 7003, 8006, 8011, 8021, 8079.

Standard: JIS, AISI, ASTM, GB, DIN, EN, etc.

Stock: 8000 Ton/Month.

Quality control: Third Part Inspection is acceptable.

Delivery Time: Within 3 days for our stock size, 15-20days for our production.

Aluminum sheet is a very common material with good forming performance, corrosion resistance, weld-ability and medium strength. It is widely used to make airplane oil tank, oil pipe, as well as the transportation vehicles, ships’ metal parts, instrument, lamps stent and rivet, metal products, electrical enclosure, etc.

3003 aluminum manganese alloy series is a common product. Due to the manganese alloy element, this product has excellent antirust properties. Its strength is about 10% higher than that of 1100, and its formability, solubility and corrosion resistance are good.

3003 Aluminum sheet is used to process parts with good formability, high corrosion resistance and good weldability, or work with these properties and higher strength than 1xxx alloy, such as kitchen utensils, food and chemical products processing and storage devices, tanks and tanks for transporting liquid products, various pressure vessels and pipes processed with thin plates, general utensils, heat sinks, cosmetic plates, etc Photocopier cylinder, ship material.

| Product name | 3003 Aluminum sheet |

| Material | 1000 Series: 1050,1060,1071,1080,1100,1435,etc. 2000 Series: 2011,2014,2017,2024,2A12,2A16,2A06,etc. 3000 Series: 3002,3003,3004,3104,3204,3030,3A21,etc. 4000 Series: 4A01 5000 Series: 5005,5025,5040,5052,5056,5083,5A05,5754, etc. 6000 Series: 6003,6060, 6061, 6082,6083,6063,6061,etc. 7000 Series: 7003,7005,7050,7075, 7085etc. |

| Standard | ASTM, JIS, SUS, EN, DIN, GB, etc. |

| Thickness | Sheet: 0.1 mm- 2.0mm Normal sheet: 0.15 mm- 2.0mm Medium plate: 6.0 mmt-25.0mm Plate: 25mm-200mm Super thick plate: more than 200mm |

| Width | 50mm-2500mm or as the customer’s request |

| Length | 50mm-8000mm or as the customer’s request |

| Surface | Oxidation, embossed, mill, bright, polished, hair line, brush, sand blast, checkered, etc. |

| OEM Service | Perforated, cutting special size, doing flatness, surface treatment, etc |

| Delivery Time | Within 3 days for our stock size,15-20days for our production |

| MOQ | 5 Ton |

| Sample | Free and available |

| Packaging | Export standard package: bundled wooden box, suit for all kinds of transport, or be required. |

| Container Size | 20ft GP: 5898MM(Length)*2352mm(Width)*2393mm(High) 40ft GP: 12032mm(Length)*2352mm(Width)*2393mm(High) 40ft HC: 12032mm(Length)*2352mm(Width)*2393mm(High) |

| Application | Construction, decoration, hardware, electric appliances, machinery and other industrial andcivil purposes, sucaselectroniccapacitor, compositecooker, rice cooker, refrigerator, computercasting, telecommunication, equipment, lampshade, air conditioner, cosmetics coverand so on. |

| 3003 Chemical Composition | |||||||||

| Al | Si | Cu | Mg | Zn | Mn | Ti | Ni | Fe+Ni | Fe |

| Margin | ≤0.60 | 0.05-0.20 | --- | ≤0.10 | 1.00-1.50 | --- | --- | --- | ≤0.70 |

| 3003 Mechanical Property | |||

| Tensile Strength (Mpa) |

Yield strength (Mpa) |

EL (%) |

Density (g/cm³) |

| 140-180 | ≥115 | ≤2% | 2.75 |

3003 is al Mn alloy, which is one of the most widely used antirust aluminum. The strength of this alloy is not high (slightly higher than that of industrial pure aluminum) and can not be strengthened by heat treatment. Therefore, cold working method is adopted to improve its mechanical properties: it has high plasticity in annealing state, good plasticity in semi cold hardening, low plasticity in cold hardening, good corrosion resistance and good weldability, Poor machinability. It is mainly used for low load parts that require high plasticity and good weldability and work in liquid or gas medium, such as oil tank, gasoline or lubricating oil conduit, various liquid containers and other low load parts made by deep drawing: wire rod is used for rivets.

1. Complete annealing: 390-430 ℃; With the different effective thickness of the material, the holding time is 30-120 min; At the speed of 30-50 ℃ / h, it is cooled to 300 ℃ with the furnace, and then air cooled.

2. Rapid annealing: 350-370 ℃; With the different effective thickness of the material, the holding time is 30-120 min; Air or water cooled.

3. Quenching and aging: quenching 500 ~ 510 ℃, air cooling; Artificial aging 95 ~ 105 ℃, 3 h, air cooling; Natural aging 120h at room temperature.

1. Cracks, corrosion spots and traces of nitrate are not allowed on the surface.

2. Peeling, bubbles, surface roughness and local mechanical damage with depth less than 8% of the nominal wall thickness of the defect location are allowed on the surface, but the maximum depth of the defect shall not exceed 0.5mm, and the total area of the defect shall not exceed 5% of the total area of the plate.

3. The supplier is allowed to polish the profile longitudinally until the surface is smooth.

4. Other requirements: prepared by the demander and the supplier.

5. The surface of the aluminum plate is bright, without scratches, and the plates pressed out by the machine are few.

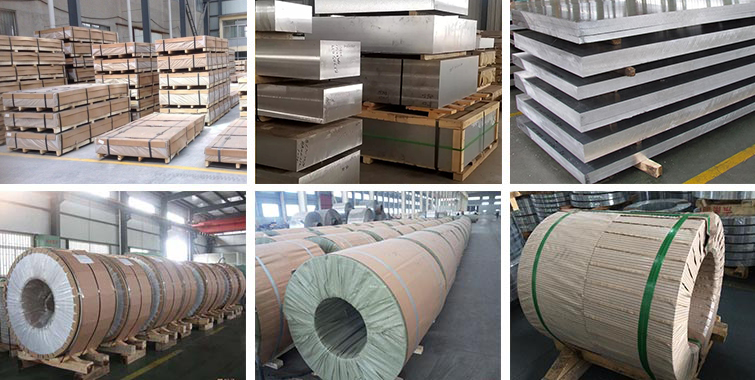

We are factory and have plenty of inventory, can meet various needs.

The product of 3003 is often used in packaging, mechanical parts, refrigerators, air conditioning ventilation pipes and other humid environment, the product has good rust resistance. It is commonly used in ships, ships, vehicles, automobile and aircraft plate welding parts, pressure vessels requiring strict fire protection, refrigeration devices, television towers, drilling equipment, transportation equipment, missile components, armor, etc.

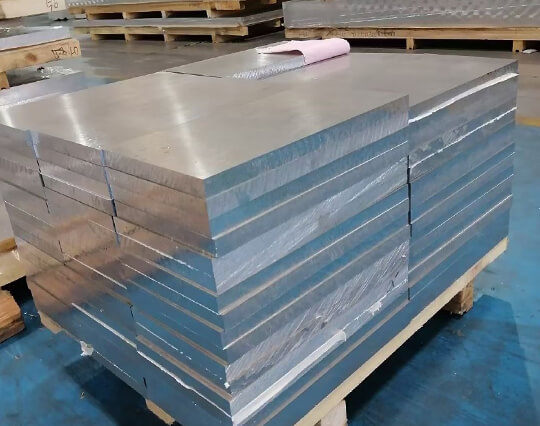

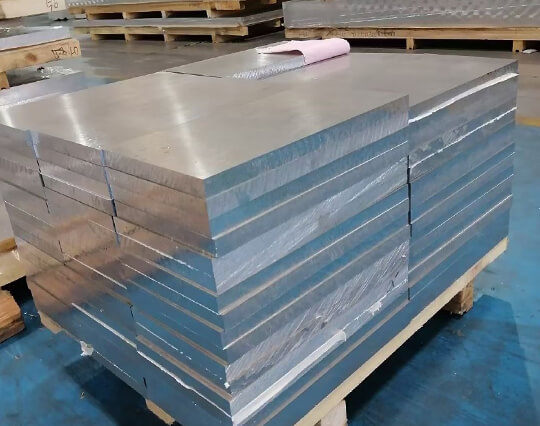

1. Standard seaworthy export packing, wooden pallets with plastics protection for the coil and sheet;

2. 15-20MT can be loaded into 20’container and 21-24MT is more suitable in 40’container;

3. The other packing can be made based on the customer requirement;

4. Normally, we have four layers of packing: wooden pallets, hardboard, Kraft paper and plastic. And fill more desiccants into package;

5. Eye to wall or eye to sky for coils.

We are factory wholesale price, and the prices are lower than 95% of suppliers. Our professional quotation will help you with your project. Expecting our long-term cooperation. )