Thickness: 0.1-300mm, or as customer’s requirements.

Width: 100-3000mm, or as customer’s requirements.

Material: 1050, 1060, 1070, 1080, 1100, 2011, 2014, 2017, 2024, 2A12, 2A16, 2A06, 3002, 3003, 3004, 3104, 3204, 3030, 3A21, 5005,5025, 5040, 5052, 5056, 5083, 5086, 5182, 5754, 5A05, 6003, 6060, 6061, 6082, 6083, 6063, 6061, 7003.

Standard: JIS, AISI, ASTM, GB, DIN, EN, etc.

Stock: 6000 Ton/Month.

Quality control: Third Part Inspection is acceptable.

Delivery Time: Within 3 days for our stock size, 15-20days for our production.

Color coated aluminum coil provides a new type of raw materials for the construction industry, shipbuilding industry, vehicle manufacturing industry, home appliance industry, electrical industry, Curtain wall decoration, Aerospace engineering, Mechanical mould, Automotive industry, etc.

| Product Name | 3003 Color Coated Aluminum Coil/Sheet |

| Alloy | 1000 Series: Industrial Pure Aluminum(1050,1060 ,1070, 1100) 3000 Series: Aluminum-manganese alloys(3A21, 3003, 3103, 3004, 3005, 3105) 5000 Series: Al-Mg alloys(5052, 5083, 5754, 5005, 5086,5182) 6000 Series: Aluminum Magnesium Silicon Alloys(6063, 6061, 6060, 6351, 6070, 6181, 6082, 6A02) 7000 Series: Aluminum, Zinc, Magnesium and Copper Alloys(7075, 7A04, 7A09, 7A52, 7A05) |

| Temper | H42 H44 H46 H48, O, H12 H22 H14 H24 H16, etc |

| Thickness | 0.013mm to 5mm |

| Width | For coil: 600mm ~ 1800mm, or as request |

| For sheet: 20mm ~ 1500mm, or as request | |

| Color | White series, Black series, Silver, Gold, Blue, Red, Wooden grain, Stone etc, or as the customer's request |

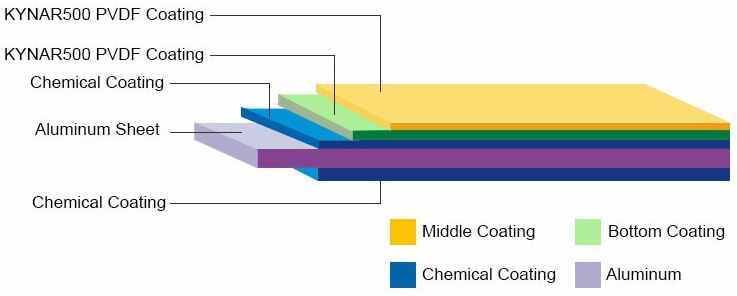

| Coating | AC, PE, Double-PE, HDPE, PVDF and FEVE. |

| Coating Thickness | PVDF Thickness: 25micron PE: 16-18(single coating), 25micron(double coating) Back coating: 5-8micron |

| Weight/Coil | As the customer's request |

| MOQ | 3 ton |

| Delivery time | Aound 30 days |

| Supply Ability | 450000 Ton/Tons per Year |

| Payment terms | T/T L/C D/P D/A |

| Packing | 3 layers of packing. Inside is craft paper, Middle is water plastic film and outside GI steel sheet to be covered by steel strips |

PE Coating

high molecular polymer as monomer and addition of alkyd,is an UV-resistant coating.It can be classified matt and glossy according to coating gloss.The compact molecule structure,makes paint surface luster and smooth ,which assure good printing on the panel surface.With an warranty of 8-10 years for weather resistance,it is specially applied for internal decoration and sign board.

PVDF Coating

PVDF coating mainly refers to a vinylidene fluoride homopolymer or a copolymer of vinylidene fluoride and other small amount of fluorine-containing vinyl monomer.The chemical structure is stable and firm,and the physical properties of the fluorocarbon coating make the PVDF coated aluminum coil better wear resistance,impact resistance, fading resistance, and UV resistance.

1. No color difference.

2. High flatness.

3. Smooth surface, no grain and small hole on the surface.

4. Hard to be polluted.

5. Easy to be cleaned.

6. High wearability, a warranty of outdoor using for 20 years.

| 3003 Chemical Composition | |||||||||

| Al | Si | Cu | Mg | Zn | Mn | Ti | Ni | Fe+Ni | Fe |

| Margin | ≤0.60 | 0.05-0.20 | --- | ≤0.10 | 1.00-1.50 | --- | --- | --- | ≤0.70 |

| 3003 Mechanical Property | |||

| Tensile Strength (Mpa) |

Yield strength (Mpa) |

EL (%) |

Density (g/cm³) |

| 140-180 | ≥115 | ≤2% | 2.75 |

1. ISO Verified Outstanding Manufacturer.

2. The third party inspection: SGS, BV, CE, COC, AI and other.

3. Flexible Payment : T/T, LC, O/A, CAD, DAP , KUNLUN Bank.

4. Sufficient Stock.

5. Quick delivery time and Long time price validity.

6. Tracking picture of transport : production, Loading and reinforcement loading pictures.

7. Rich experience professional sale team.

1. Quality Guarantee after Receiving the Goods: Offer money return or Ship new products for free.

2. If any problems happen.

3. Technical Guidance for further Processing.

4. VIP Service and Free Order after Accumulated Order Quantity.

5. The competitive advantage of product line.

6. The company has many years of industry experience.

Color coated aluminum coil provides a new type of raw materials for below industry:

Packaging: 3 layers of packing. Inside is craft paper, Middle is water plastic film and outside GI steel sheet to be covered by steel strips with lock, with inner coil sleeve.

Shipping: We have long-term cooperation with many experienced shipping companies and will find the most suitable mode of transportation for you.

We are factory wholesale price, and the prices are lower than 95% of suppliers. Our professional quotation will help you with your project. Expecting our long-term cooperation. )