Thickness: 0.1-300mm, or as customer’s requirements.

Width: 100-3000mm, or as customer’s requirements.

Material:1050, 1060, 1070, 1080, 1100, 2011, 2014, 2017, 2024, 2A12, 2A16, 2A06, 3002, 3003, 3004, 3104, 3204, 3030, 3A21, 5005,5025, 5040, 5052, 5056, 5083, 5086, 5182, 5754, 5A05, 6003, 6060, 6061, 6082, 6083, 6063, 6061, 7003.

Standard: JIS, AISI, ASTM, GB, DIN, EN, etc.

Stock: 8000 Ton/Month.

Quality control: Third Part Inspection is acceptable.

Delivery Time: Within 3 days for our stock size, 15-20days for our production.

5052 aluminum coil is used to process parts with good formability, high corrosion resistance and good weldability, or work with these properties and higher strength than 1xxx alloy, such as kitchen utensils, food and chemical products processing and storage devices, tanks and tanks for transporting liquid products, various pressure vessels and pipes processed with thin plates, general utensils, heat sinks, cosmetic plates, etc Photocopier cylinder, ship material.

| Product Name | 5052 Aluminum Coil |

| Material | 1050, 1060, 1070, 1080, 1100, 2011, 2014, 2017, 2024, 2A12, 2A16, 2A06, 3002, 3003, 3004, 3104, 3204, 3030, 3A21, 5005,5025, 5040, 5052, 5056, 5083, 5086, 5182, 5754, 5A05, 6003, 6060, 6061, 6082, 6083, 6063, 6061, 7003 |

| Temper | H111 H112 H116/H321 H12/H22/H32 H14/H24/H34/H16/H26/H36 H18/H28/H194,etc |

| Standard | ASTM, JIS, SUS, EN, DIN, GB, etc. |

| Thickness | 0.1-300mm |

| Width | 100-3000mm |

| Length | Coils /According to customer requirements |

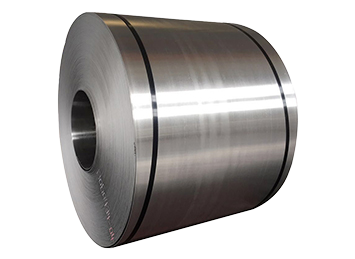

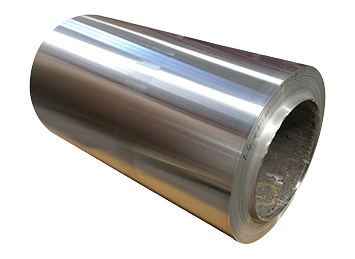

| Surface | Smooth and flat , Embossed, Polished, Mirror, Bright, Polished, Hair line, Brush, Sand blast, Checkered, Etching, etc |

| Advantage | 1. Good malleability 2. Light-weight 3.Good electrical and thermal conductivity 4. High reflexes and oxidation resistance |

| Application | 1. Widely used in aircraft, cars, trains, ships and other manufacturing industries. In addition, space rocket, space shuttle,artificial satellite also use a large number of aluminum and its aluminum alloy 2. Electrical appliance manufacturing industry, wire and cable industry and radio industry 3. Manufacture all kinds of heat exchangers, cooling materials and cookers 4. Medical instruments, refrigeration units, ceilings in building interiors,Etc. |

| Payment Term | TT/LC/After Copy of the BL |

| Delivery Time | Within 3 days for our stock size,15-20days for our production |

| MOQ | 5 tons |

| Sample | Free and available |

| 5052 Chemical Composition | |||||||

| Al | Si | Cu | Mg | Zn | Mn | Cr | Fe |

| Margin | ≤0.25 | ≤0.10 | 2.2~2.8 | ≤0.10 | ≤0.10 | 0.15~0.35 | ≤0.40 |

| 5052 Mechanical Property | ||||

| Tensile Strength (Mpa) |

Yield Strength (Mpa) |

Modulus of elasticity (E) | Density(g/cm³) | Annealing temperature |

| 170-305 | ≥90 | 69.3~70.7Gpa | 2.72 | 345℃ |

5052 is Al Mg alloy. Magnesium is the main alloy element in 5052 alloy, which is the most widely used antirust aluminum. This alloy has high strength, especially fatigue strength: high plasticity and corrosion resistance, can not be strengthened by heat treatment, good plasticity in semi cold work hardening, low plasticity in cold work hardening, good corrosion resistance, good weldability, poor machinability and polishing.

Aluminum magnesium alloy also contains a small amount of manganese, chromium, beryllium, titanium, etc. In addition to a small amount of solid solution, most of the manganese in the alloy forms mnal6. The effect of chromium in 5052 aluminum is similar to that of manganese, which can improve the resistance to stress corrosion cracking, improve the strength of base metal and weld, and reduce the tendency of welding crack, but its content is generally less than 0.35%.

1.Quality Assurance

Select the right ingredients, Cast product

2.Diversified Product

Product specifications and models are diverse, can meet customer's requirement

3.Adequate Stock

Multiple warehouses,timely delivery

4.After-Sale Guarantee

There are independent teams to solve problems for you

1.It is used for manufacturing aircraft fuel tank, oil pipe, sheet metal parts of traffic vehicles and ships, instrument, street lamp bracket and rivet, hardware products, electric appliance shell, etc.

2.5052 aluminum alloy is one of the most widely used antirust aluminum, which has high strength, especially anti fatigue strength: high plasticity and corrosion resistance, can not be strengthened by heat treatment, good plasticity in semi cold work hardening, low plasticity in cold work hardening, good corrosion resistance, good weldability, poor machinability and polishing ability. It is also mainly used for low load parts that require high plasticity and good weldability and work in liquid or gas medium, such as oil tank, gasoline or lubricating oil conduit, various liquid containers and other low load parts made by deep drawing: wire rod is used for rivets.

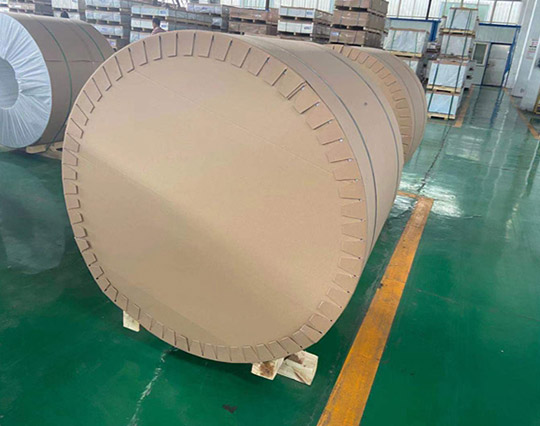

1.The aluminum is placed with waterproof paper, and steel strip packed, which is suit for all kinds of transport, or as required.

2.Port: Qingdao, Shanghai or your request.

3.Container:

20 FT GP: 5988 mm (length) x 2352 mm (width) x 2393 mm (height), loading 18 to 25 tons.

40 FT GP: 12032 mm (length) x 2352 mm (width) x 2393 mm (height), loading 20 to 28 tons.

We are factory wholesale price, and the prices are lower than 95% of suppliers. Our professional quotation will help you with your project. Expecting our long-term cooperation. )